Himmelfarb Staff Member 3D Prints Face Shields for Health Care Workers

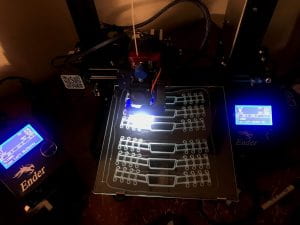

John Lopez, Himmelfarb Library’s Data Technician, has joined an initiative to 3D print face shields for healthcare workers. John shares how he became involved in the project, and what the process entails.

How did you learn about the face shield printing initiative?

I initially read an article about a hospital in Brescia, Italy which was hit hard by the pandemic. They were running out of valves used for their respirators which the manufacturer couldn't provide quickly enough, so a small startup company reversed engineered the valve and began 3D printing them, which the hospital then used. The article quickly became viral just as COVID-19 reached the states.

I began noticing online 3D printing communities around the world organizing similar efforts once Josef Prusa - the founder of Prusa Lab in Prague, Czech Republic - released an open-source face shield design, made available for anyone with a 3D printer to produce. Various iterations were soon released, but the Prusa face shield design proved to be the most effective among health care workers.

Are you partnering with a particular organization or initiative?

I joined the volunteer effort started by Open Works, a makerspace workshop based in Baltimore who were among the first to mobilize volunteer makers with an organized and efficient plan to provide face shields to local healthcare systems and hospitals. A chain of custody is established via email registration, as each 3D print file is assigned a unique parts number which helps keep track of how many face shields were printed by a volunteer.

What part of the shield is 3D-printed? What other materials do you need for assembly, and where can you get them? Is there a standard for what material the face shield should be made of (e.g., thickness)?

The face shield is actually a printable headband, as well as a printable chin strap which serves as a mount for the visor; both are included in the 3D print file. An elastic cord, along with the actual clear acrylic visor, are required to complete assembly, both of which are done at Open Works once they receive completed face shields.

PETG is the type of filament material primarily used to print the face shields, which can be purchased on Amazon for example. It's preferred due to its rigidity and because it can be sterilized more efficiently than other types of printing material such as PLA. There is indeed a printing guideline for makers to follow which sets the parameters to prevent the face shield from breaking.

How long does it take to print the shield frames?

The average print time when following the recommended print settings can take up to 6 hours for a single face shield. There are certainly a variety of ways to print faster by tinkering with hardware, such as changing the nozzle size, but it's not encouraged as strength and quality of the model are prioritized over speed.

Are you using the library’s 3D printer?

I'm grateful for my two 3D printers at home since the library's 3D printer service hasn’t been accessible.

Roughly how many have you assembled so far?

Volunteers had been asked to print at least three face shields each during the early weeks of the pandemic. The incredible response from volunteers reached a saturation point in mid-April as thousands of face shields had been made. Since then my focus has been printing ear straps for face masks.

Once they’re assembled, how do you get them to their destination?

Once a face shield is done printing, I wear nitrile gloves to remove the part from the print bed and follow the sanitation checklist provided by Open Works. A liability waiver is also signed then sent along with the face shields through USPS.

Is there a website (or several websites) you would recommend people visit for more information?

A good starting point for anyone with a 3D printer looking to join local volunteer efforts in their area

COVID-19 Supply Chain Response: Essential Information

https://3dprint.nih.gov/collections/covid-19-response/essential-info

Article re: 3D printed valve parts used in hospitals throughout Italy

https://www.bbc.com/news/technology-51911070

Blog post from Josef Prusa about face shield design

https://blog.prusaprinters.org/from-design-to-mass-3d-printing-of-medical-shields-in-three-days/

Open Works/Makers Unite/We the Builders - the volunteer org I had joined for printing the face shields

https://www.wethebuilders.com/projects/11

The group was mentioned in a recent article from The Economist:

NIH’s 3D Print Exchange now has downloadable designs for PPE and devices, including the Prusa face shield and face mask ear savers:

Prusa Protective Face Shield

https://3dprint.nih.gov/discover/3dpx-013409

Surgical Mask Tension Release Band for Ear Comfort & Extended Use