Silicon (Si) is an attractive active material in Li-ion battery anodes due to its low cost, high abundance, non-toxicity, and high gravimetric and volumetric capacity - Si has 10x more Li-ion storage capacity than graphite. Currently, anodes use only 2-3% Si mixed with graphite due to cost and electrode expansion. Thus, demand for high energy density and longer-lasting batteries makes Si very valuable.

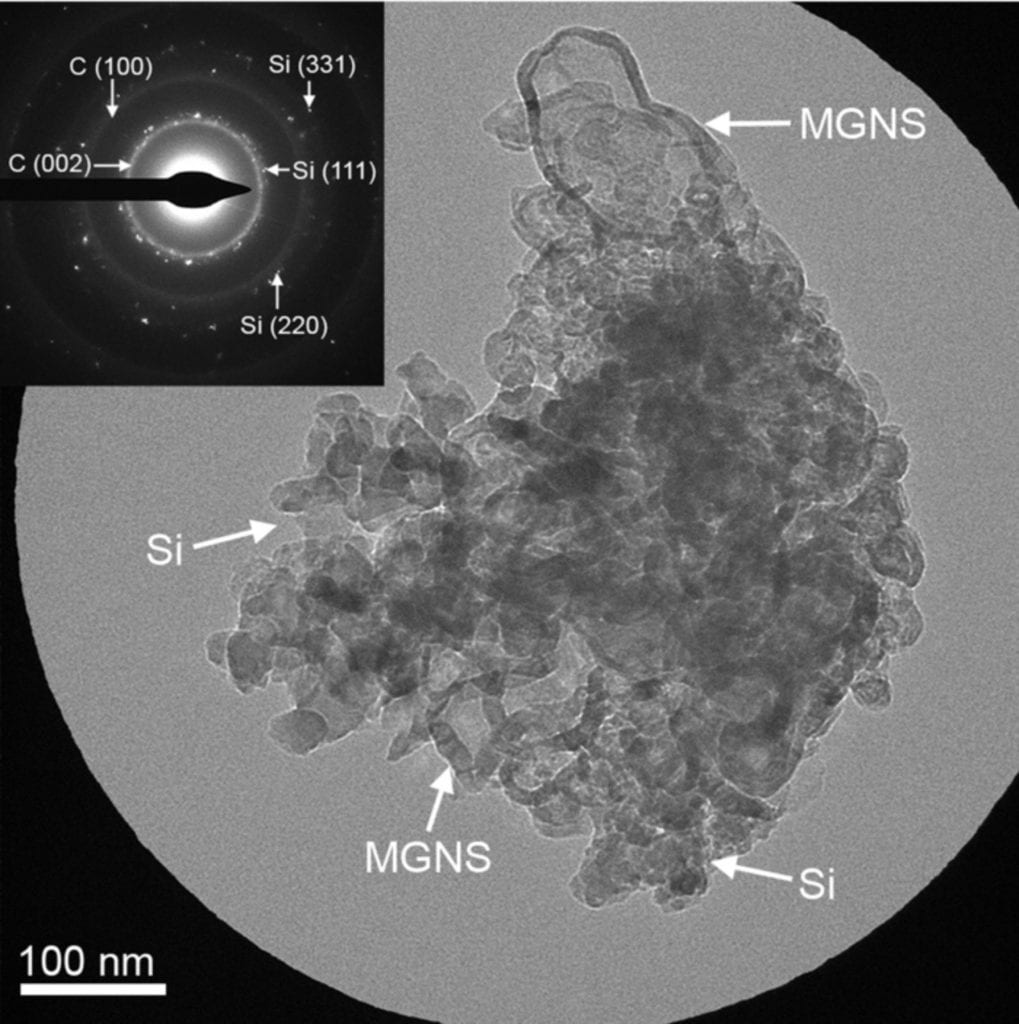

When used in Li-ion batteries Si undergoes a large volume expansion as it soaks up Li like a sponge, thereby expanding 300% upon lithiation. Si expansion/contraction on lithiation/delithiation causes cracking and fracturing in bulk Si and micron-size particles. Si nanoparticles of less than 150nm do not crack upon lithiation/delithiation and are cycling efficiently. However, the production of Silicon nanoparticles has many shortcomings: expensive; poorly scalable techniques; gas-phase silane thermal decomposition; wide particle size distribution, and the large particles causing mechanical failure. In addition, the Si nanoparticles form a thick passivation layer/shell (SiO2) on their surface and the excess shell needs to be removed by using Hydrofluoric Acid (HF) which is extremely hazardous. In our lab, we have developed a much less expensive and economically feasible method for manufacturing anode grade Nano-Si.

If you are interested in learning more about this project, contact current graduate student Dustin Abele by email here.