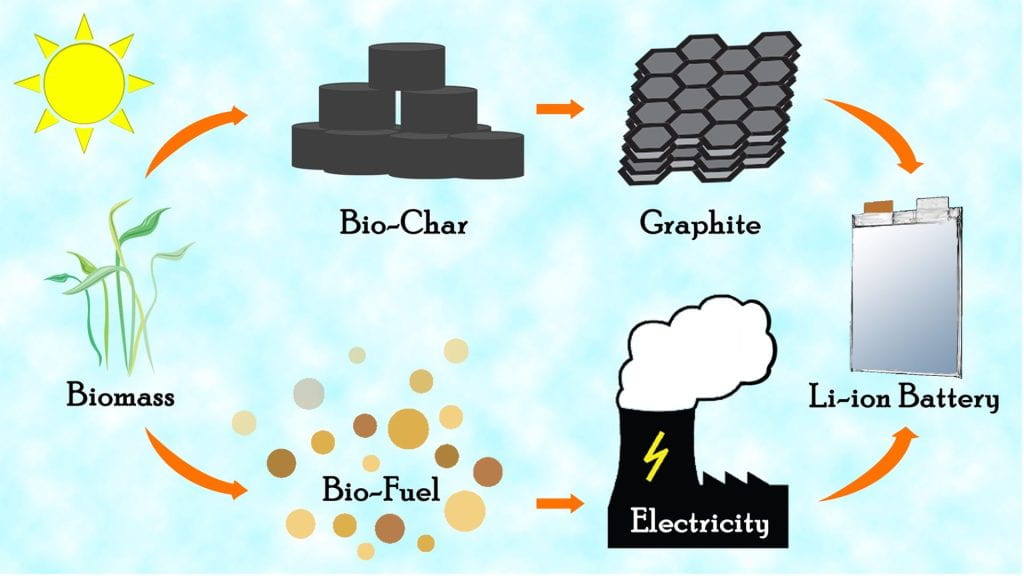

Graphite from Biomass

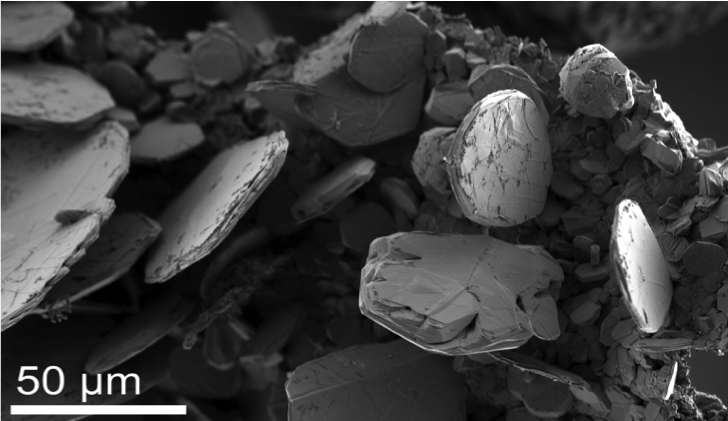

We have developed a carbon negative, green and inexpensive method for the synthesis of graphite from biomass, a remarkable discovery given that biomass is considered "ungraphitizable". Our method produces highly crystalline, highly pure, battery grade graphite that is comparable to commercial grade graphite, valorizating biochar, a waste product of the biofuel industry. Our work may help mitigate climate change while providing a clean source of graphite for electric vehicles and other lithium-ion battery devices. Simple adjustments to the process parameters allows the control of flake size from a few microns to many millimeters, allowing the production of graphite that is customized for its numerous industrial applications including refractories, metallurgy, expanded graphite, carbon brushes, conductive additives, and of course, Li-ion battery anodes.

Rational Control of Graphite Synthesis

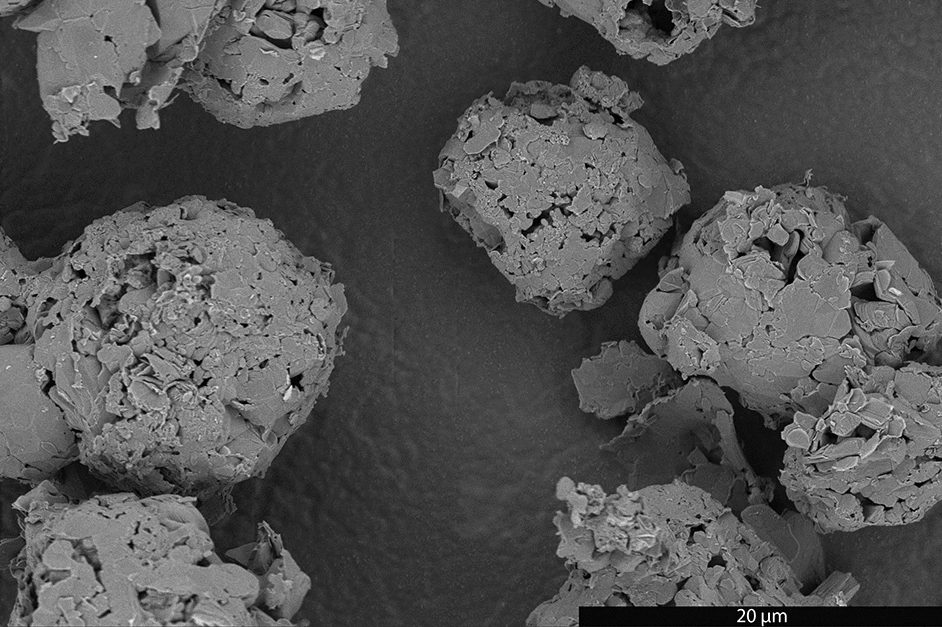

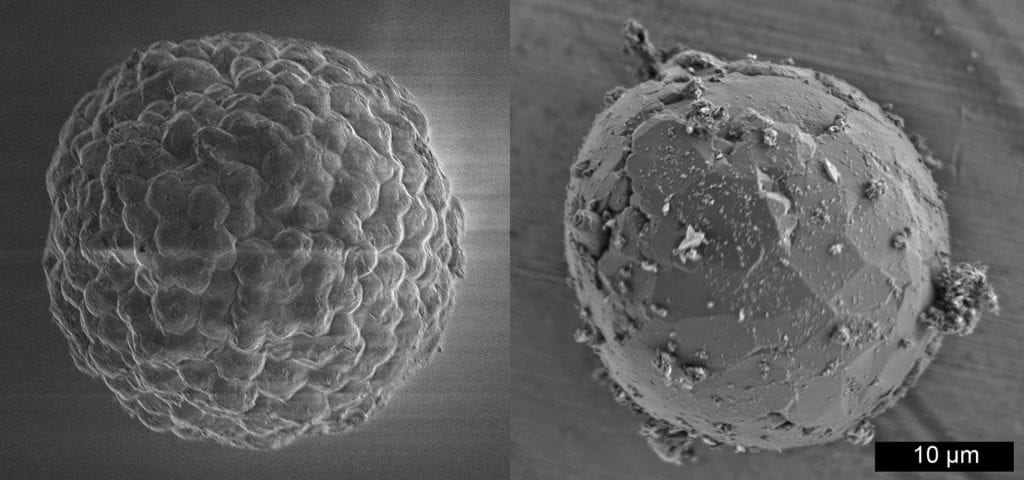

We have demonstrated and are exploring further our ability to directly engineer the morphology of the graphite agglomerates from the relatively malleable biomass, with no loss of graphite. Shaping is a necessary step to produce graphite for Li-ion batteries (read about graphite for Li-ion batteries here). Our method is in direct contrast to commercial graphite production in which ~ 70% of starting graphite is lost during the shaping process, with dramatic industrial and environmental costs (read about the commercial graphite processing for Li-ion batteries here). Our method allows low-cost synthesis with morphologic control without a wasteful shaping process while still producing high grade graphite for use with Li-ion and Si/graphite composite battery anodes.

Alternative Materials for Graphite Synthesis

We synthesized graphite from other materials such as lignite coal, waste carbons such as paper or cardboard, farm and poultry waste, and char byproducts from other industrial processes, exploring the limits of materials that can be used as a carbon source for our synthesis method.