Plastic has become an inevitable, near unavoidable part of our lives in the 21st century. Its pervasiveness makes it difficult to view each piece of plastic as something so detrimental to our environment. But it hasn’t been this way for very long–the rapid increase in the use of plastic is a relatively new phenomenon of the past couple of decades.

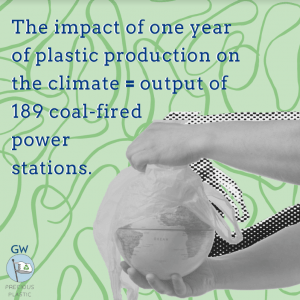

Around the world, we now produce over 300 million tons of plastic waste every year. However, in 1990, we produced 120 million tons. How has this issue gotten so out of hand so quickly? And where is all of this waste going? The story of plastic reveals a convoluted tale of corporations valuing profits over all else and the dangerous trope of “out of sight, out of mind.”

The creation of plastic has undeniably served the world in positive ways–medicine, science, and technology likely would not be where it is today without the use of plastics. This, however, is not why plastic waste has doubled since 1990.

Today, single-use plastics make up 50% of yearly plastic waste. In other words, the accumulation of seemingly benign items like plastic bags – which are used for an average of 12 minutes – are choking our environment with plastic waste.

It is easy to immediately blame those who don’t bring their own reusable grocery bags to the store or who don’t carry around a Nalgene everywhere they go. It’s important to recognize, however, that the plastic industry and large beverage corporations directly shaped this consumer-focused narrative and continue to benefit from it today.

In the years before the first Earth Day in 1970, environmental demonstrations across America decried the issue of throw-away containers, holding manufacturers responsible for the waste crisis the country was beginning to see unfold.

The Keep America Beautiful campaign–backed by corporation giants like Coca-Cola–responded to this call for change by rapidly shifting the narrative of blame back on the consumer through a series of targeted, emotional advertisements that convinced the American public that pollution was, in fact, the individual’s fault.

Recycling, since then, has been seen as a way in which consumers can do their duty of keeping the environment plastic-and-trash-free. But the recycling system as we know it is broken. Worldwide, under 20% of plastics are recycled, while 25% is incinerated and the remaining 55% is discarded, with much finding its way to the ocean. In the United States, recycling rates are even worse at around 8%.

Since the 1980s, the majority of our recyclables had been shipped to China to be processed and recycled. In 2018, China changed their waste-management policies and banned nearly all imports of foreign trash.

The United States simply does not have the recycling infrastructure in place to deal with the astounding 34 million tons of plastic waste produced every year, and as such, more plastics have been added to the landfill or burned. Rather than improve our recycling systems, the U.S. has continued to export our problems to countries that are economically vulnerable.

Countries in Southeast Asia have been flooded with Western garbage in overwhelming quantities since 2018 and are then blamed as being the top polluters in the world. Recycling and the education around it has not been a priority in this country, and the consequences of our wasteful decisions are ones that we are not forced to face on a daily basis.

The plastic industry has been selling us convenience for decades, and we’ve been buying it. Many of us have grown up in an age where we’ve known nothing but a throw-away economy that craves ease above all else. The recycling system in America contributes to this mindset, as it is often assumed that as long as we throw everything in the recycling bin, we are doing enough for the planet.

But to actually combat this waste crisis and plastic pollution, the recycling system in this country must be overhauled. Small-scale solutions like Precious Plastics have shown innovative possibilities that transform how waste is viewed. Furthermore, the issue of plastic use itself must be reckoned with.

Large corporations have created a world where sustainable options are more costly, time consuming, and seemingly inconvenient. However, those of us who have the privilege to make environmental changes in our lives have a responsibility to do so.

The idea around waste needs to change. We should be mindful about where our trash goes and the consequences our decisions could have not only on the environment but on people around the world.

At the same time, no one should forget that the top three plastic polluters in the world are Coca-Cola, PepsiCo, and Nestlé – three colossal corporations with an abundance of resources and money to either stop proliferating single-use plastics or to find innovative alternatives.

While plastic pollution has been a corporation-pushed problem, we as consumers must fight for the solution or change will simply never come and profits will continue to determine the fate of our planet. In the face of the climate crisis, our futures depend on immediate action and a complete upheaval of many facets of our society, including how we accumulate and dispose of waste.

The drastic change that this planet needs to fight climate change and pollution will not come unless those who have the means to do so show corporations and the plastic industry that single-use plastics are no longer acceptable–not only through their day-to-day choices, but in the demands they make of their elected officials, as well.